| Product Name | Carbon Steel Pipe/Boiler Steel Pipe |

| Materia | A53 GrB,A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65,X70 |

| Standard | API 5L,ASTM A106 Gr.B,ASTM A53 Gr.B,ASTMA179/A192,ASTM A335 P9,ASTM A210,ASTM A333 |

| Testimonia | API 5L,ISO9001,SGS,BV,CCIC |

| Diameter exterior | 13.7mm-762mm |

| Murum crassitudine | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100, SCH120, SCH160, XS, XXS |

| Longitudo | 1m, 4m, 6m, 8m, 12m secundum petitionem emptoris |

| Superficiem treatment | nigrum pingunt, glutine, oleum, galvanized, odii corrosio obductis |

| Vestigium | Vexillum notati, vel secundum tuam request.Marking Methodo: Imbre album pingunt |

| Curatio finis | Patet finis / Bevelled finem / finem sulcatus / Threaded finem Cum Plastic Caps |

| Ars | Hot Rolled or cold Rolled ERW |

| sarcina | Solve sarcina, packaged in fasciculos (2Ton Max); tibiae fundis ad utrumque finemfacilem loading ac missionem, ligneacasibus, IMPERVIUS texta pera |

| Test | Chemical Component Analysis, Proprietates Mechanicae, Proprietates Technicae, Magnitudo Exterior Inspectio, hydrau probatio, X-ray Test |

| Applicationem | Liquida partus, organum organum, constructio, petroleum crepuit, fistula oleum, fistula gast |

API 5L X42-X80, PSL1&PSL2 Oleum et GasCarbon Seamless Steel Pipeadhibetur ad gas, aquam, et petroleum tam olei quam naturalis gasi industriarum transportandum.

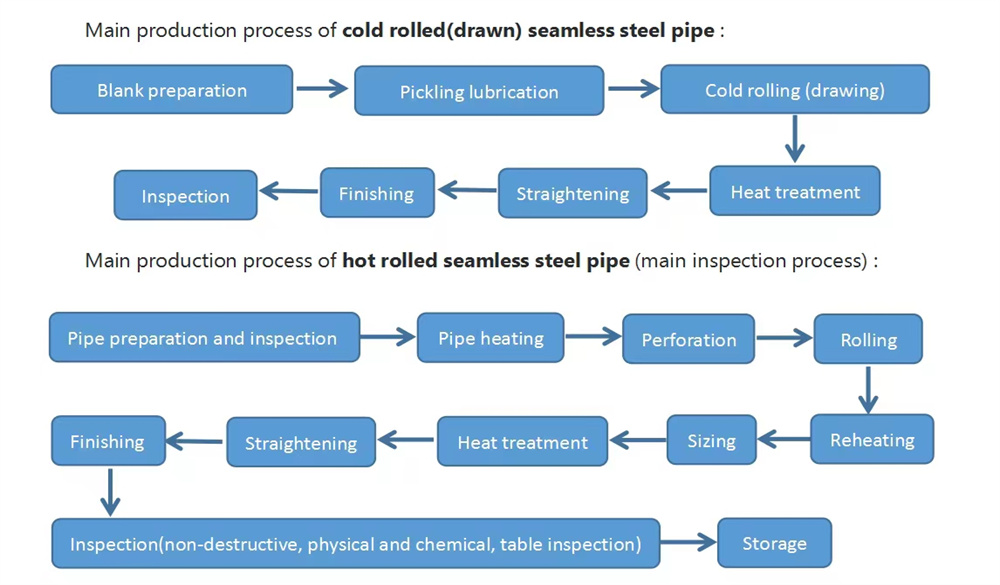

API 5L X42-X80, PSL1&PSL2 Oleum et Gas Carbonis Seamless Ferro Pipe fiunt vel frigido-tracto vel calido involuto, ut mos erat postulatus.

API 5L X52 PSL1&PSL2 Oleum et Gas Carbonis Seamless Chalybis Pipe fiunt vel frigido-tracto vel calido involuto, normaliter parvae magnitudinum quae a frigore tracto et magnis magnitudinibus calidis convolvuntur.

Gradus et Chemical Compositio (%)Nam API 5L PSL1

| Standard |

Gradus | Chemical compositione(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.28 | ≤1.30 | ≤0.030 | ≤0.030 |

| X46,X52,X56 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X60, X65 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X70 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X52 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

Gradus et Chemical Compositio (%)Nam API 5L PSL .2

| Standard |

Gradus | Chemical compositione(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤0.24 | ≤1.30 | ≤0.025 | ≤0.015 |

| X46,X52,X56 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X60, X65 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X70, X80 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X52 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

Mechanica Proprietates API 5L GR.B X42-X80/X52(PSL1).

| Gradus | Cedat imperium(MPa) | Distrahentes fortitudo(MPa) | Prolongatio A% | ||

|

| psi | MPa | psi | MPa | Prolongatio (Min ) |

| X42 | 42,000 | 290 | 60,000 | 414 | 21~27 |

| X46 | 46,000 | 317 | 63,000 | 434 | 20~26 |

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

| X56 | 56,000 | 386 | 71,000 | 490 |

|

| X60 | 60,000 | 414 | 75,000 | 517 |

|

| X65 | 65,000 | 448 | 77,000 | 531 |

|

| X70 | 70,000 | 483 | 82,000 | 565 |

|

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

Mechanica proprietates API 5L/X52GR.B Seamless Line Pipe (PSL2).

| Gradus | Cedat imperium(MPa) | Distrahentes fortitudo(MPa) | Prolongatio A% | Impact (J) | ||

|

| psi | MPa | psi | MPa | Prolongatio (Min ) | Min |

| X42 | 290 | 496 | 414 | 758 | 21~27 | 41(27). |

| X46 | 317 | 524 | 434 | 758 | 20~26 | 41(27). |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27). |

| X56 | 386 | 544 | 490 | 758 |

|

|

| X60 | 414 | 565 | 517 | 758 |

|

|

| X65 | 448 | 600 | 531 | 758 |

|

|

| X70 | 483 | 621 | 565 | 758 |

|

|

| X80 | 552 | 690 | 621 | 827 |

| |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27). |

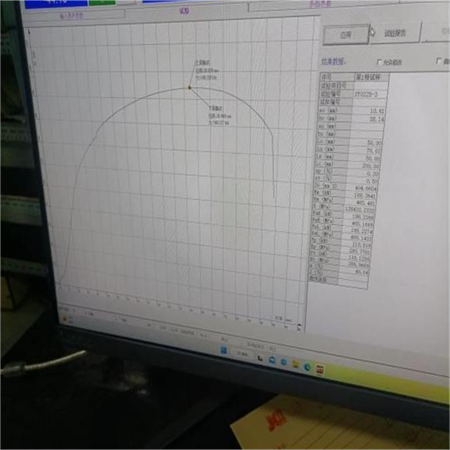

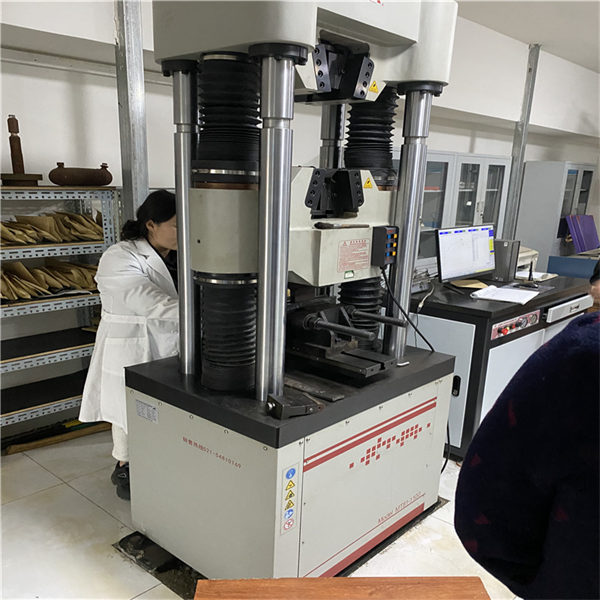

Mechanica Testis

duritia Testis

flectere Testis

Tentatio tensilis organi corporis — Testium tensile ad normam ISO6892 vel ASTM A370. Specimina longitudinalia adhibenda sunt. Bis per experimentum unitatis fistulae cum ratione abd frigida expansionis eadem.

Adulatione test-Unus test adulatio fietur in speciminibus ab unoquoque fine duorum fistularum ex unaquaque sorte electae.

CVN test impulsus - Charpy test ferri debet secundum ASTM A370.Unitas bis per experimentum non plus quam 100 longitudinum fistulae cum ratione expansionis frigidae eadem abd

Duritia Test — Cum suspecta durae maculae per inspectionem visualem deprehenduntur, duritia probationum perficietur ad normam ISO 6506, ISO 6507, ISO 6508 vel ASTM A 370 utens durities portatilis test instrumentorum et methodorum cum ASTM A 956, ASTM A 1038 vel ASTM E 110 respective secundum methodum Used.

Hydro-static Test-Utraque tubus testi pressioni hydro-staticae subiecta erit

Inflexio test — satis longum fistulae per 90° circum cylindricum mandrel inflexa frigescit.

C% X-ray test ad pugillo commissura

Ultrasonic probatio

Examen torsit current

Fistula nuda seu Black / Varnish coating (secundum requisita mos);

6" et infra in fasciculis cum duabus fundis bombicis;

Desinit utrumque patronis;

Finis campus, finem revellere (2" et supra revellere fines, gradus: 30~ 35°, lina et copulatio;

Observans.

| Magnitudo | Tolerantia (cum respect tO extra certadiametri) |

| <2 3/8 | + 0.016 in., - 0.031 in. (+ 0.41 mm, - 0.79 mm). |

| > 2 3/8 et ≤4 1/2, continua iuncta | ±1.00% |

| > 2 3/8 et < 20 | ±0.75% |

| > 20. inconsutilem | ± 1.00% |

| 20 et <36, conflati | + 0.75%.-0.25% |

| > XXXVI, iuncta est | + 1/4 in.. - 1/8 in. (+ 6.35 mm, -3.20 mm). |

ln fistula hydro-statim probata ad pressuras in excessu pressurarum mensurarum, aliae tolerantiae inter artificem et emptorem convenire possunt.

| Out-of-Roundness | |||||

| Magnitudo | Minus tolerantia | Plus tolerantia | Finis-ad-finem tolerantia | Diameter, Axis TOLERATIO (Sentio certa OD) | Maximum differentiale inter minimum et maximum diametri (solum ad Pipe Cum D / t≤75) |

| ≤10 3/4 l&V4 | 1/64(0.40mm) | 1/16(1.59mm) | - | - | |

| >10 3/4 et ≤20 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | - | - | - |

| > 20 et ≤ 42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | <0.500 in. |

| >42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | £ Q625 in. |

Ex rotunditate tolerantiae maximas et minimas diametros applicant ut mensuratur METIOR, caliper, seu fabrica mensurandi diametrorum maximorum et minimorum actualium.

Diameter mediocris (ut mensurata cum taenia diametri) unius tibiae extremitatis non plus quam 3/32 in (2,38 mm) differt.

| Magnitudo | Genus Pipe | Tolerance1 (Sentio de Wall Crassitudo certa} | |

| Gradus B vel inferioris | Gradus X42 vel Superior | ||

| <2 7/8 | Omnis | +20.- 12.5 | + 15.0.-12.5 |

| >2 7/8et<20 | Omnis | + 15,0,-12.5 | + 15-I2.5 |

| >20 | iuncta | + 17.5.-12.5 | + 19.5.-8.0 |

| >20 | Inconsutilem | + 15.0.-12.5 | + 17.5.-10,0 |

Ubi tolerantiae negativae minores quam recensentur ab emptore specificatae sunt, tolerantia positiva augebitur ad applicabilem totalem tolerantiam in cento minus parietis crassitudinis tolerantiae negativae.

| quantitas | Tolerance (percent) |

| Singulae longitudinis, speciales fistulae campanae vel A25 pipeSingula longitudinum alia fistulaCarloads.GradeA25,40,000lb (18 144kg) velCarloads, praeter Gradus A25,40.0001b (18 144 kg) vel plusCarloads, omnes gradus minus quam 40000 lb (18 144 kg) Ordo item.Gradualia a25.40.000 lb (18 144 kg) vel amplius Ordo rerum, praeter Gradus A25,40,000 lb (18 144 kg) vel plus Ordo item, omnes gradus, minus quam 40.000 lb (18 144 kg) | + 10.-5.0 + 10,- 35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Notae:

1. Pondus tolerantiae ad pondera calculata pro tibia lina et copulata et ad pondera tabulata vel calculata ad fistulam plani finem applicata.Ubi parietis negativi crassitudo tolerantiae minor quam quae in mensa supra recensita sunt ab emptore specificantur, plus pondus tolerantia unius longitudinum augebitur ad 22,5 centesimis minus plangentibus, crassities tolerantia negativa.

2.Pro carlo- ribus fistulae ex pluribus item ordinis compositis, tolerantiae onerariae singulis ordinis item fundamentis applicandae sunt.

3. Tolerantia ordinis supellex applicatur ad summam fistulae quantitatem ad ordinem item exigendum.